Company: ASML, Eindhoven, the Netherlands

Industry: Manufacturing of Lithographic Scanners Used in the Production of Semiconductors

Role: Developmental Engineering Coop

Duration: September 2015 – December 2015

Overview: I was given one project to work on during my time at ASML. The goal of the project was to optimize the leak locating strategy used by ASML for air circuits (and possibly extend it to water circuits). Before my arrival, the circuits were leak tested using pressurized air to confirm that a leak was present in the system (based on a threshold of pressure drop after 1 hour). After which, the leak was localized by spraying parts of the circuit that were prone to leakages with a soapy water solution, and visually noting the formation of bubbles. The method was both outdated, and had a system downtime of approximately 4 days. I was required to conduct research on the system requirements and quantify the leak rates associated with the circuit, build a prototype scaled down circuit of the system to recreate the predetermined leaks, and test different tools and select the optimum to detect these leaks.

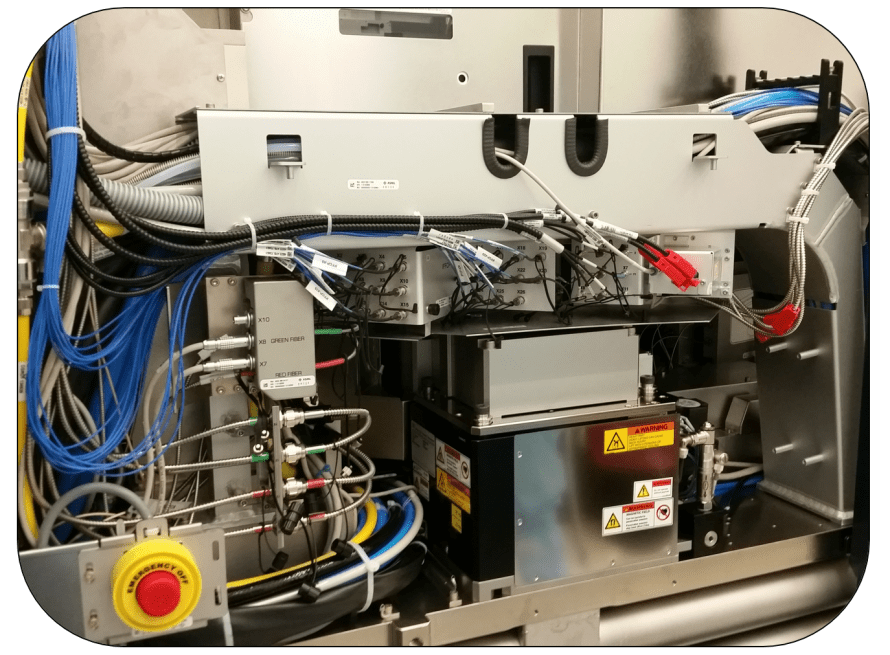

Details: Initially, the leak rates associated with the system (shown as the blue tubes in the image below) had to be quantified. This required analyzing detailed circuit drawings and applying fluid dynamic calculations (such as Bernoulli’s equation and Ideal Gas Laws).

Air Pressurized Circuit Under Analysis

Based on the threshold for pressure drop per hour that was considered acceptable at the company, and calculating the overall circuit volume to being approximately 60 liters, the magnitude of “unacceptable” leak rates in the system ranged from 0.05 mbar-l/s to 0.005 mbar-l/s.

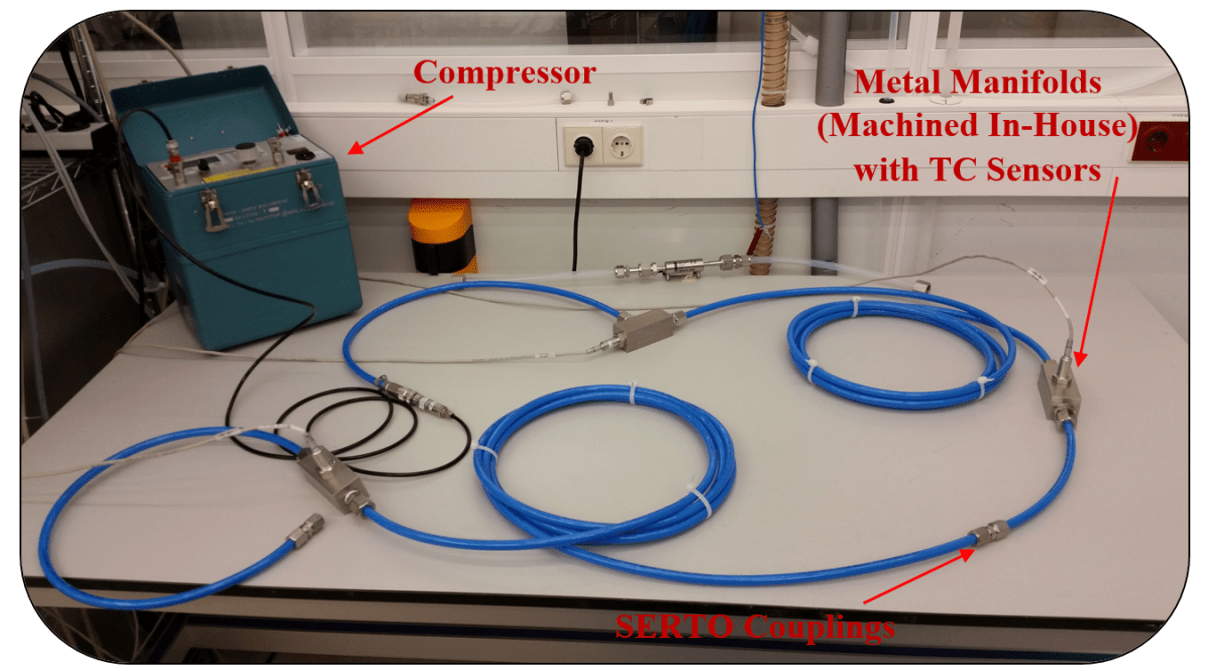

Next, I constructed a scaled down prototype circuit in order to recreate the same order of magnitude of leaks. The circuit contained short-nose thermocouple sensors (temperature sensors) and a compressor (pressure sensor) in order to note when the circuit reached thermal equilibrium after it was pressurized, and to monitor the pressure drop of the circuit over time. Several segments of tubing were connected to metal manifolds (which housed the temperature sensors) and each other using SERTO compression fitting couplings. The setup looked as follows.

Prototype Setup to Replicate Leak Rates

The circuit shown above was able to create leak rates at a single site in the order of magnitude of 0.001 mbar-l/s (an order of magnitude lower than the acceptable leak rate). This was done by carefully unwinding one of the SERTO couplings (labelled in the diagram) using 2 wrenches. Next, I did research on several tools capable of detecting leaks of our magnitude, and contacted multiple vendors to obtain feedback.

Tool Utilizing Ultrasound Monitoring Technology

I narrowed it down to 3 tools, utilizing infrared thermography, ultrasound monitoring (shown in the image to the right), and tracer-sniffer gas methods. Once my manager approved of my research, I sourced the tools and created testing protocols for each to see which performed best. I even asked a lab technician unfamiliar with all 3 methods to test each, and considered that in selecting the optimum method.

My results showed the optimum leak locating method to be using a hydrogen tracer gas with a sniffer tool. The company will be able to reduce B-time (unexpected downtime) by a factor of at least 25% based on my findings, and they were going to implement in after the end of my internship.

Skills Gained:

- I got the opportunity to apply my fluid dynamics technical knowledge to a real-life application through this internships, and successfully quantified details of the system.

- I learned how to analyze detailed circuit drawings, and read blueprints of a system.

- I gained hands-on experience in a cleanroom environment, and learned how to assemble a prototype circuit using pressure sensors and temperature sensors. This also allowed me to get familiarized with various types of circuit couplings.

- I contacted vendors and sourced tools utilizing 3 distinct technologies. This involved negotiating time frames for testing, and cost for rental of these tools.

- I created testing protocols, wrote several written reports, and presented on numerous occasions to teams of 20 or more people on the process of optimizing the leak location methods. My findings effectively reduced the system downtime by 25%.